Why do we need non-contact connectors?

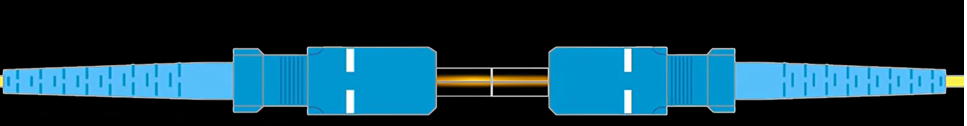

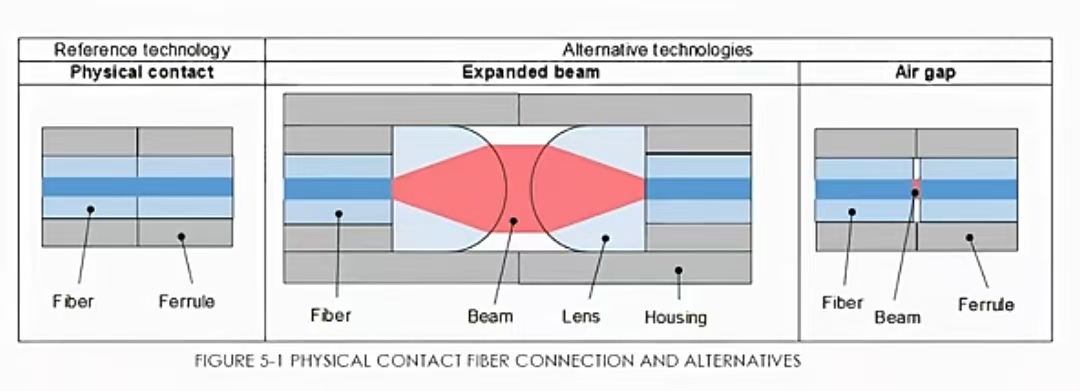

Over the past forty years, optical fibers have always relied on physical contact, requiring two fibers to be closely joined for signal transmission. This is easily achievable with single optical fibers,like SC LC FC connector .

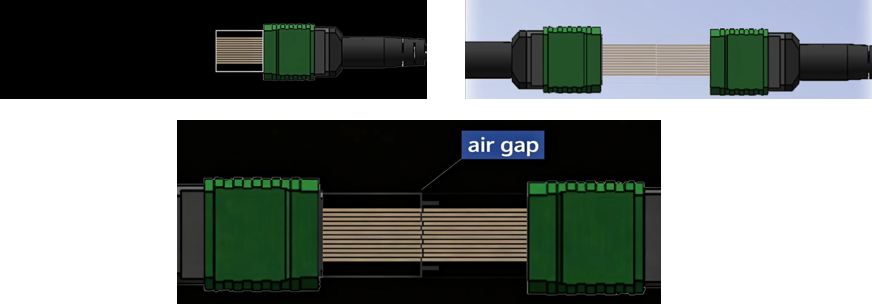

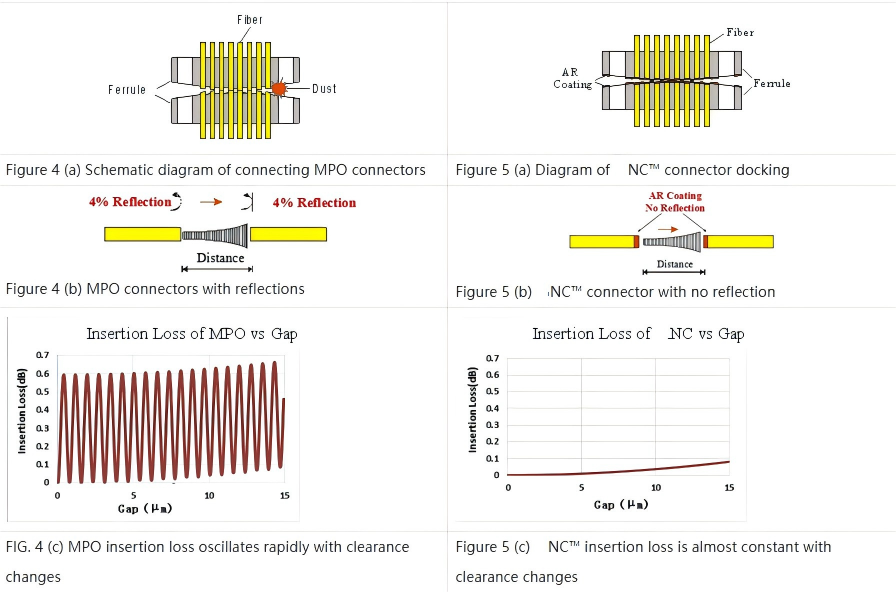

But in multi-fiber connectors such as MPO and MTP, it is impossible to ensure full contact between all fiber cross-sections. Some fibers have micron-level gaps, leading to multiple reflection issues. Moreover, in certain application scenarios, connectors are frequently plugged and unplugged, which can easily damage the fiber contact points and result in unstable optical signals.

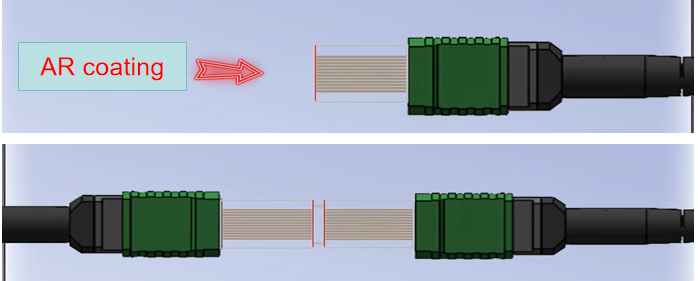

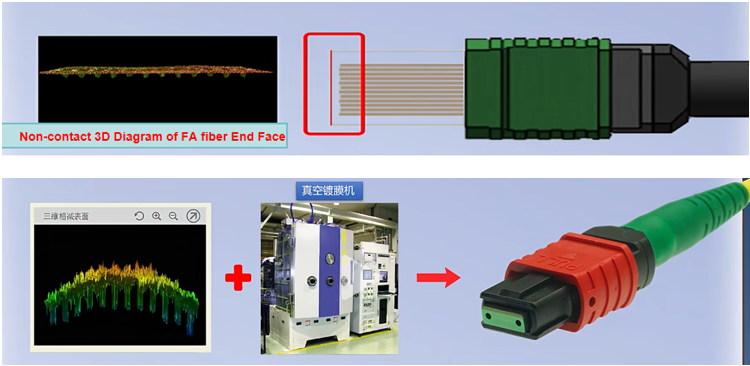

To Solve these problems, industry engineers have developed non-contact optical fiber connectors, achieving a fundamental breakthrough in traditional contact-based connections. Its core principle consists of two key steps. First, to eliminate the impact of multiple reflections caused by gaps in MPO connectors on performance, an anti-reflection coating is applied to the fiber end faces. The coating eliminates multiple reflections, enabling efficient transmission of optical signals without compromising performance. Second, to protect the anti-reflection coating on the fiber cross-sections from damage, the ferrules are fabricated with a special under-fiber height process. This design recesses the fibers several microns below the ferrule surface, actively creating a stable physical non-contact gap.

In simple terms, a non-contact connector is essentially composed of recessed fibers and anti-reflection coatings. Compared with traditional MPO connectors, it boasts significantly enhanced performance and superior resistance to dust and contamination. In 2017, Huawei proposed it to the International Electrotechnical Commission (IEC) as a new international standard for "dust-proof optical fiber connectors". In 2019, it was included in the technical white paper by the Consortium for On-Board Optics (COBO), officially recognized worldwide as the third category of optical fiber connectors.

The Applications of Non-contact Fiber Optic Connectors

Non-contact MPO connectors are mainly used in high-density optical connection scenarios that demand high reliability, cleanliness, and longevity.

1. Data centers/cloud computing rooms

- High-speed interconnection of high-density optical modules (e.g., QSFP-DD, OSFP), avoiding end-face contamination/wear caused by frequent plugging and unplugging, and improving connection stability.

- Long-cycle optical links between cabinets/racks (reducing maintenance costs).

2. Aerospace/defense equipment

- Optical communication links for airborne/shipborne equipment (resistant to vibration and shock, no physical contact wear).

- High-density optical signal transmission for precision equipment such as radars and satellites (adapting to extreme temperature and humidity environments).

3. Industrial automation and high-end manufacturing

- Dynamic optical connections for robot joints and rotating worktables (no contact wear, supporting infinite rotation).

- Cleanroom optical communication in semiconductor/panel production lines (avoiding end-face contamination that affects yield).

4. Medical equipment

- Optical signal transmission for high-end imaging equipment (e.g., MRI, CT) (no electromagnetic interference, meeting the cleanliness requirements of medical environments).

- Wireless optical connections for wearable/implantable devices (non-invasive, no physical contact risks).

What is the cost of non-contact fiber optic connectors?

As a manufacturer of optical cables and MPO fiber jumpers, Kexint has extensive experience in producing non-contact MPO and MTP jumpers, and we are capable of providing this product to customers at the lowest cost.