GYXTC8A the fibers,250μm,are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. The two sides PSP are longitudinally applied over the outer loose tube. Steel wires and loose tubes filled with water proof compound to ensure compact and longitudinally water blocking ,this part of cable accompanied with the stranded wires as the supporting part are completed with a polyethylene(PE) sheath.

Detail Information | |||

| Outer Jacket: | PE Or HDPE | Fiber Count: | 12/24/48/72/96/144 |

| Fiber Type: | G652D/G657A1/G657A2 | Fiber Brand: | Corning/YOFC/FIBERHOME |

| Messenger: | 8.0*1.0mm Or 7.0*1.0mm | Length Per Roll: | 2km To 4km |

| Marking: | Embossed Printing Or Printing | Application: | Outdoor Aerial Application |

| High Light: | armored network cable,armored fiber cable | ||

12/24/48/96 SM-fibers.

G652D operating wavelength at 1260~1625nm.

FRP(PE coated) as central strength member.

Loose buffer tubes SZ-stranded.

The buffered tube filled with filling compound while the stranded core covered with water blocking tape.

Aramid yarns and aluminum tape armored.

PE Cable Outer sheath and messenger wires combined.

Suitable as: Aerial installation.

Reference Standard

IEC 60793-1, 60793-2, 60794-1

ITU-T G650, G652

Optical and mechanical characteristics of fiber

| MFD(1310nm) | 9.2mm±0.4mm |

| MFD(1550nm) | 10.4mm±0.8mm |

| Cladding diameter | 125mm±1.0mm |

| Fiber diameter | 250 ± 15 mm (Colored) |

| Cladding non circularity | £1.0% |

| Cut off wavelength | £1260nm |

| Attenuation coefficient | 1310nm: £0.35dB/km |

| 1550nm: £0.215dB/km | |

| Bending-loss performance of optical fiber | £0.05dB |

| Polarization mode dispersion | £0.1ps/Ökm |

| Zero-dispersion wavelength | 1300 – 1324 nm |

| Zero-dispersion slope | £0.092ps/(nm2•km) |

Mechanical requirements and methods of fiber cable

| Tensile strength | 2850N, conform to IEC 794-1-E1 while fiber strain is ≤0.33% |

| Crush | 2200N/100mm, conform to IEC 794-1-E3 |

| Impact | conform to IEC 794-1-E4 |

| Repeated bending | conform to IEC 794-1-E6 |

| Temperature cycling test | conform to IEC 794-1-F1 |

Each fiber will be identifiable throughout the length of the cable in accordance with the following color sequence. Fiber color in each tube starts from No. 1 Blue.

| Fiber color code | 1 | 2 | 3 | 4 | 5 | 6 |

| Blue | Orange | Green | Brown | Slate | White | |

| 7 | 8 | 9 | 10 | 11 | 12 | |

| Red | Black | Yellow | Violet | Rose | Aqua |

Tube color coding Product Structure Diagram

The loose tubes will be identifiable in accordance with the following color sequence, and each tube with 12 fibers. If there are fillers, the color is natural.

| Fiber color code | 1 | 2 | 3 | 4 | 5 | 6 |

| Blue | Orange | Green | Brown | Slate | White | |

| 7 | 8 | 9 | 10 | 11 | 12 | |

| Red | Black | Yellow | Violet | Rose | Aqua |

Product Structure Diagram

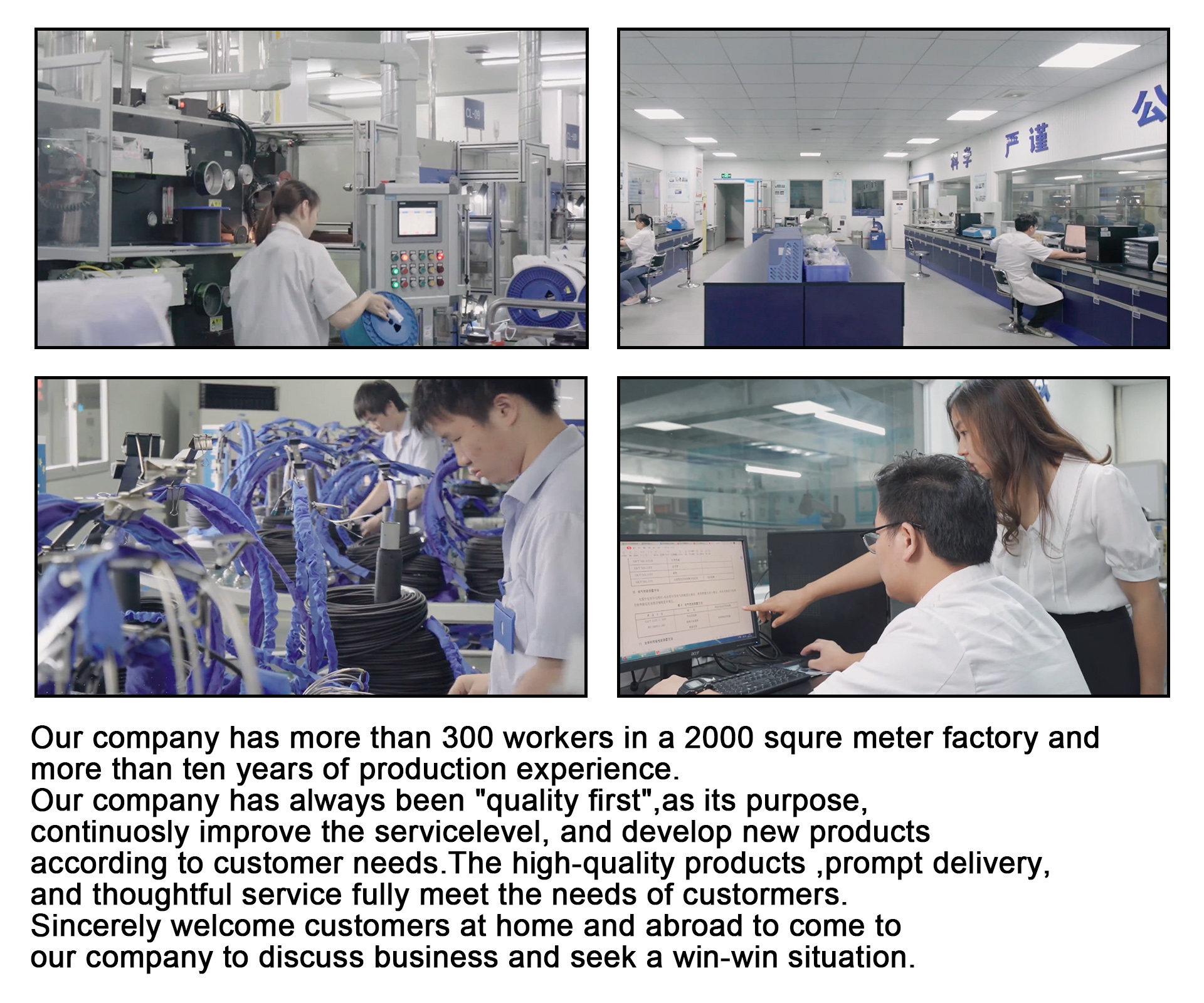

Coloring Workshop

Package and Shipping:

1. All of our fiber optic cable package are with export wooden drum.

2. 2~3km/drum, Outdoor fiber optic cable's wooden dimension is 110cm*110cm*71cm, 0.85CBM,

3. Can be load about 39 drums for a 20GP.

Also accept custom cable drum from customers. welcome to contact us!

CONTACT US

Take advantage of our unrivaled knowledge and experience, we offer you the best customization service.

SEND US A MESSAGE

HOTLINE

+8613509645699

EMAIL

RECOMMENDED

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.