Cable design:

12 SM-fibers (max.) placed in each tube.

Steel wire as central strength member.

Loose buffer tubes SZ-stranded.

The buffered tube filled with filling compound while the stranded core covered with water block material

Corrugated steel tape armored for rodent attack.

HDPE Cable Outer sheath.

Suitable as: Duct Installation.

1.Reference Standard

IEC 60793-1, 60793-2, 60794-1

ITU-T G650, G652

2.Optical and mechanical characteristics of fiber

| MFD(1310nm) | 9.2mm±0.4mm |

| MFD(1550nm) | 10.4mm±0.8mm |

| Cladding diameter | 125mm±1.0mm |

| Fiber diameter | 250 ± 15 mm (Colored) |

| Core/cladding concentricity error | £0.6mm |

| MFD concentricity error | £0.8mm |

| Cladding non circularity | £1.0% |

| Cut off wavelength | £1260nm |

| Attenuation coefficient | 1310nm: £0.35dB/km |

| 1550nm: £0.21dB/km | |

| Bending-loss performance of optical fiber | £0.05dB |

| Polarization mode dispersion | £0.1ps/Ökm |

| Zero-dispersion wavelength | 1300 – 1324 nm |

| Zero-dispersion slope | £0.092ps/(nm2•km) |

3.Mechanical requirements and methods of fiber cable

| Tensile strength | 1500N, conform to IEC 60794-1-E1 while fiber strain is ≤0.33% |

| Crush | 1000N/100mm, conform to IEC 60794-1-E3 |

| Impact | conform to IEC 60794-1-E4 |

| Repeated bending | conform to IEC 60794-1-E6 |

| Torsion | conform to IEC 60794-1-E7 |

| Flexing | conform to IEC 60794-1-E8 |

| Kink | conform to IEC 60794-1-E10 |

| Cable bend | conform to IEC 60794-1-E11 |

| Temperature cycling test | conform to IEC 60794-1-F1 |

| Water penetration | conform to IEC 60794-1-F5B |

| Spark test voltage | Spark test voltage of cable outer jacket will be no less than 8kV AC |

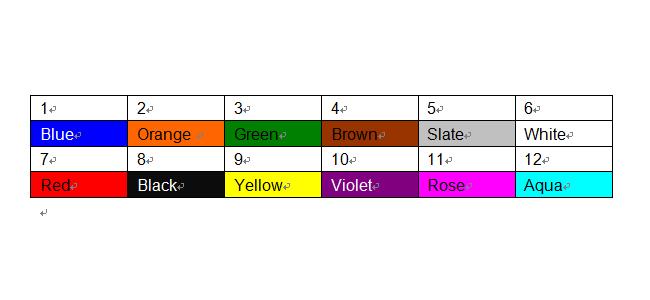

4.Fiber color coding and Tube color coding

5.Structure

6.Environmentally

The product is accord with the instruction of ISO 14001 and EU RoHS6.

7.Packing and Logo

Packing

Each single length of cable shall be wound on a wooden composite drum.

Covered by plastic buffer sheet.

Sealed by strong wooden battens.

Drum length

Standard drum length is 3000m;

Total quantity is at least the ordered quantity.

Or it can be delivered according to customers'requirements, but not longer than 5000m.

Drum Marking

Manufacturer name;

Manufacturing year and month;

Roll-direction arrow;

Cable outer end position indicating arrow;

Cable type and size;

Drum number;

Drum length;

Gross / net weight;

Caution plate indicating the correct method for loading, unloading and convey the cable;

Other customer information such as contract no., project no., and delivery destination. (if needed)

Cable identification documents

Product qualified certificate;

Test report.

Accurate volume and weight information.

Service description

The service life of cable shall not less than 25 years.

The warranty period of cable is guaranteed for 24months after the date of cable is received by destination. If quality of cable happened, delivery and pick-up charges are at the manufacturer’s expense for all repairs made under the warranty.

1. All of our fiber optic cable package are with export wooden drum.

2. 2~3km/drum, Outdoor fiber optic cable's wooden dimension is 110cm*110cm*71cm, 0.85CBM,

3. Can be load about 39 drums for a 20GP.

Also accept custom cable drum from customers. welcome to contact us!

CONTACT US

Take advantage of our unrivaled knowledge and experience, we offer you the best customization service.

SEND US A MESSAGE

HOTLINE

+8613509645699

EMAIL

RECOMMENDED

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.