Differences in structural design

1.Fiber type

Indoor optical cable: Taking multimode optical fiber as an example, 50/125μm or 62.5/125μm is suitable for short-distance, high-bandwidth applications, such as 10G transmission in data centers.

Outdoor optical cable: Single-mode optical fiber 9/125μm is mostly used, supporting long-distance, 100 kilometers, low-loss transmission.

2. Fiber core number

Indoor optical cable: Commonly used cores are 1-36 cores, and the core number is flexible and diverse. Single-core to multi-core combinations can be selected according to actual needs.

Outdoor optical cable: Commonly used cores are 4-48 cores, and some scenarios may reach hundreds of cores, and the core number is relatively concentrated. Small and medium cores are the main ones, and larger cores may be used for cross-regional transmission.

3. Reinforcement

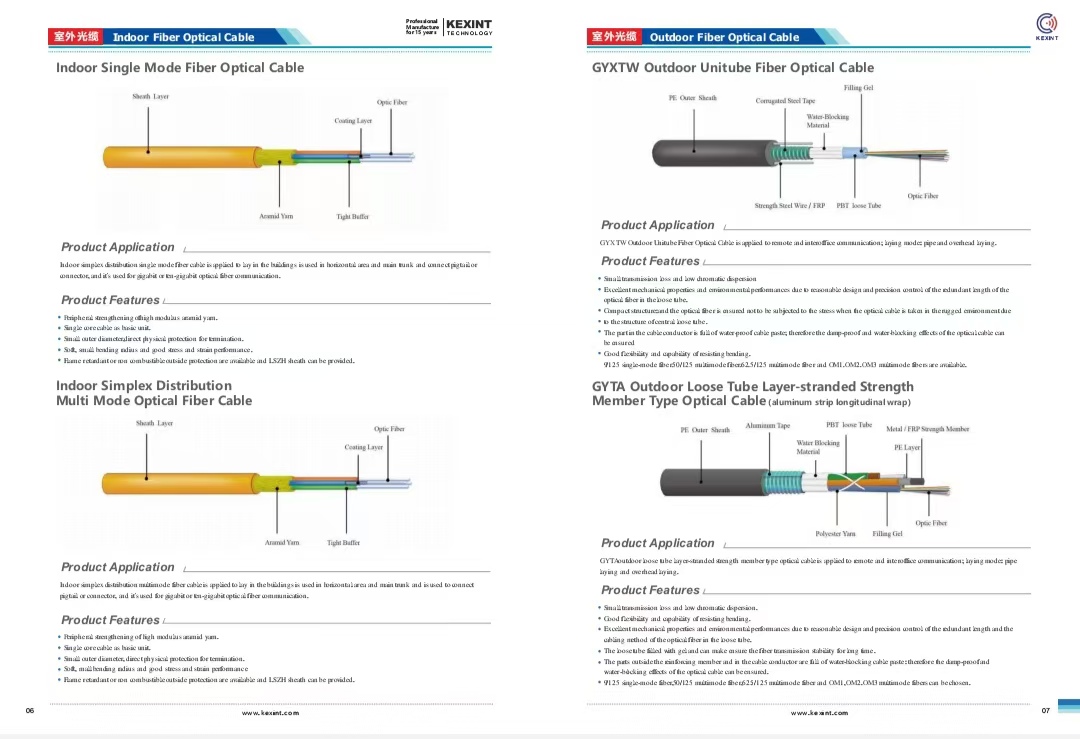

Indoor optical cable: Aramid yarn is commonly used, which is light and tensile.

Outdoor optical cable: Phosphated steel wire or FRP is used to provide high-strength tensile and compressive resistance.

4. Sheath material

Indoor optical cable: Most of them use low smoke zero halogen (LSZH) sheath, which is low smoke, flame retardant and safe to use.

Outdoor optical cable: Usually use polyethylene (PE) sheath, which has UV resistance and waterproof properties.

5. Filling material

Indoor optical cable: Usually no filling or a small amount of water-blocking material is filled to ensure lightweight.

Outdoor optical cable: Use grease filling or water-blocking yarn to prevent water vapor penetration and cause optical fiber failure.

Performance parameter difference (theoretical value)

| parameter | Indoor Fiber Optical Cable | Outdoor Fiber Optical Cable |

| Tensile Strength | 100~400N | 1000~3000N |

| Flattening force | 100~1000N/10cm | 1000~3000N/10cm |

| Bending radius | Smaller (usually 10 times the cable diameter) | Larger (needs to be adapted to overhead or direct burial) |

| Temperature range | -20~+60℃ | -40~+85℃ |

Differences in installation and maintenance

Indoor optical cable: bending radius ≥ 10 times the diameter of the optical cable, flexible construction, can be laid through pipes, cable troughs or overhead. Flame retardant properties should be noted to avoid signal interference.

Outdoor optical cable: direct burial, overhead or pipeline laying, direct burial depth ≥ 1.2 meters, tension controlled within 1500N when overhead.