01. Composition of high-density modular patch panels

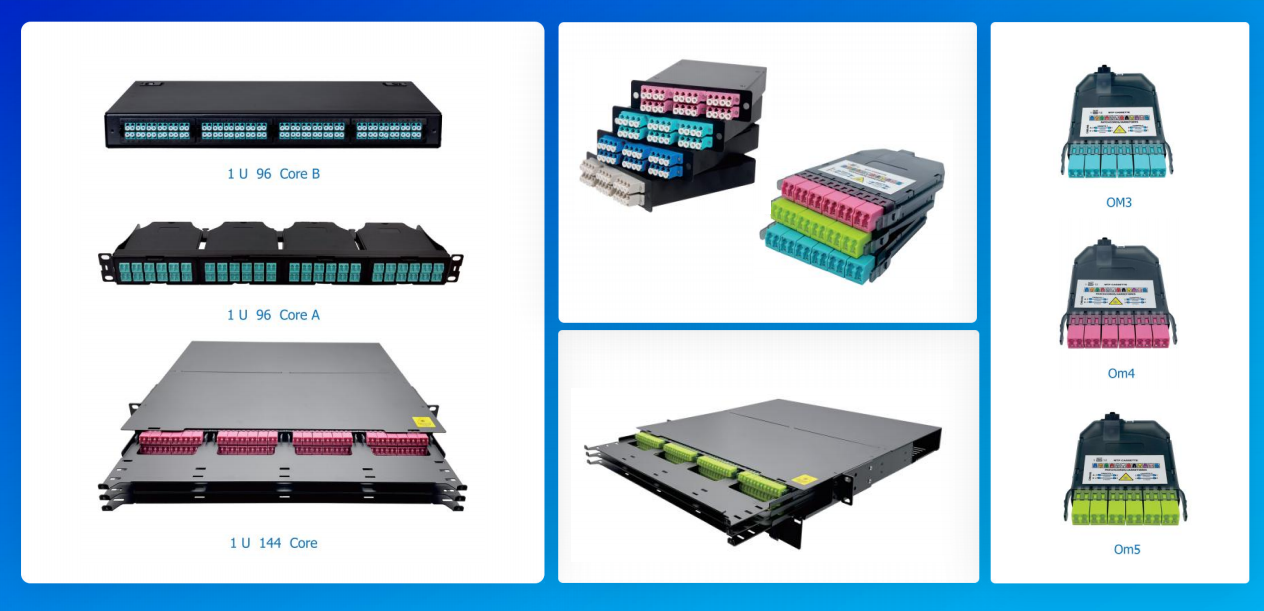

High-density modular patch panels can be used in a variety of application scenarios and are mainly composed of a cabinet and a module box. The cabinet shell is generally made of high-quality thickened cold-rolled plate material, which is resistant to pressure and impact and not easily deformed after long-term use. It is generally also equipped with a hanging ear design. A reasonable hanging ear design can adjust the front and rear distance according to the actual use of the cabinet to avoid re-drilling due to inappropriate size.

The mpo cassette can be easily snapped onto the patch panel and is easy to remove. It has high flexibility, making it easy to detect problems and perform subsequent maintenance.

02. Use of high-density modular patch panel

There are two common ways to open and use it

1. Pull-out opening

Pull-out design, metal guide rails, smooth push and pull, more flexible application, faster and more convenient debugging.

2. Integrated opening

The integrated design is equipped with a snap-on cover, which can be easily operated and opened with one button, saving time and improving efficiency.

The MPO interface is generally used for the inlet of the module box, which has low insertion loss, can accommodate a large number of cores, and realizes high-density wiring. The high-density modular patch panel can be used in a variety of application scenarios and is mainly composed of a box and a module box. The high-density modular patch panel is easy to install and can be quickly installed, removed and maintained. Its high-density wiring capacity can solve most problems such as termination, wiring, installation and maintenance operations. If the cabinet capacity of the IDC data room is limited, the MPO high-density modular patch panel can be used, which can not only meet basic usage needs, but also save space, have good flexibility, and quickly solve wiring and branching problems.